Written By Erson Cams

Photography courtesy of Erson Cams

Camshafts, and the shape of the lobes on them, can play a dramatic effect on how a vehicle performs at different engine speeds. Understanding how they work—and the different types available—will help you to maximize your four-stroke engine’s performance.

Two major types of camshafts exist: flat tappet and roller. Within those categories are two options: solid or hydraulic—four variations in all.

Tappets ride against the camshaft lobes—their movements open and close the valves. As the terms suggest, a flat tappet camshaft operates with solid flat tappets and hydraulic flat tappets, also known as lifters or followers. A roller camshaft operates with hydraulic roller lifters and solid roller lifters.

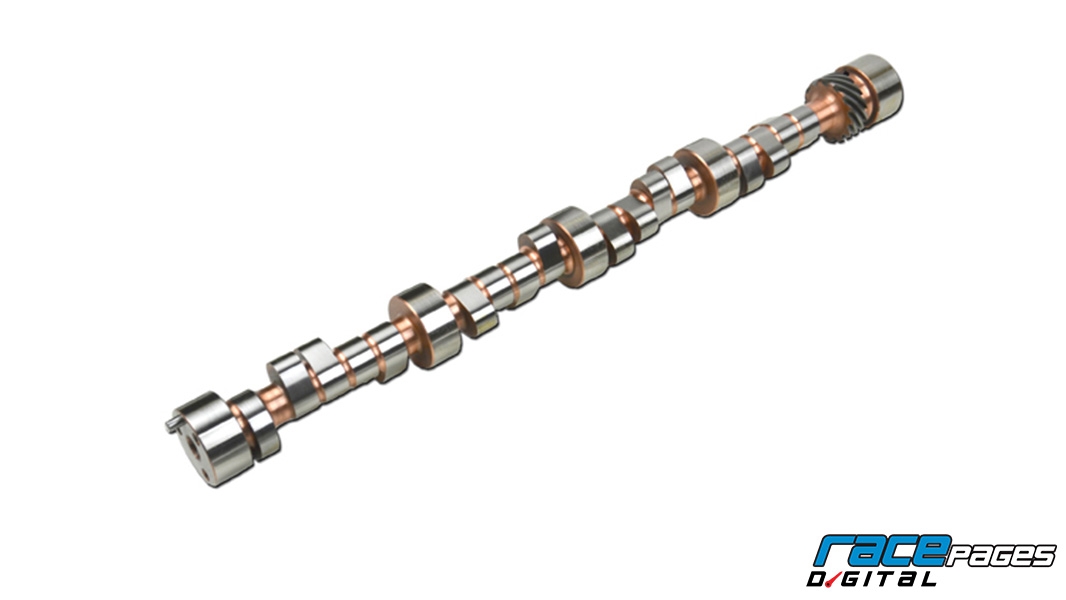

There are four different types of camshafts (hydraulic flat tappet pictured), and each one operates in conjunction with a specific tappet or lifter or follower. Never attempt to interchange them.

The chief difference between this hydraulic roller and the hydraulic flat tappet camshaft is that the former is made of steel and the latter, the hydraulic flat tappet, is formed as a “chilled iron” casting.

Hydraulic camshafts: In passenger cars of the 20th century, the hydraulic flat tappet assembly was succeeded by the hydraulic roller arrangement that became popular in the early 1980s. Though adding the roller wheel, bearing, and axle increases costs marginally to the original equipment manufacturers (OEM), the difference between the two aftermarket assemblies is substantial—the hydraulic roller costs at least three times more. But high-revving race engines require a standard far beyond OEM obligations. These include precision-ground heat-treated tool steel and stainless steel components, dedicated pressure-fed oiling, polished DLC coatings to resist abrasive wear, and exacting tolerances.

Although microscopic, there is a fascinating aspect of the solid flat tappet design. Though exaggerated in this illustration, the taper of a solid flat tappet camshaft lobe and the crown of a solid flat tappet work with single purpose: to spin the tappet in its bore and thus avoid wear.

Solid flat tappet camshafts: Though NASCAR rules switched to solid roller camshafts around 2015, solid flat tappet arrangements have been mandatory for decades. These flat tappets are lightweight and durable when made from tool steel, finished with a DLC coating, and operated in conjunction with a tool steel camshaft. Today, solid flat tappet arrangements remain compulsory in certain Circle Track racing rule books and continue to be popular in street performance engines.

The expensive solid roller assemblies hold the promise of fast valve action and high rpm. They are usually not recommended for street performance applications.The expensive solid roller assemblies hold the promise of fast valve action and high rpm. They are usually not recommended for street performance applications.

Solid roller tappet camshafts: These were used in aircraft radial engines dating back to the 1930s, and are still prominent in our domestic V8 racing engines today, particularly in drag racing engines. The introduction of the roller allows the finessing of seat times; that is, the amount of time the valves remain seated or closed. They also permit stiffer valve springs that generate high engine speeds. Note that unlike their hydraulic counterparts, both solid flat tappet and solid roller tappet assemblies require maintenance—periodic free-play checks known as “lash” adjustment.

For more information on camshafts and associated components, visit Erson Cams online at www.pbm-erson.com or call them at 800-641-7920.