While it is certainly true that there is no replacement for displacement, the real secret to making power is in the bore size. For example, the old F1 V-8 engines had a 3.85 x 1.56-inch bore and stroke. Modern Pro Stock engines aren't quite as lopsided, but are also considerably over-square. By comparison, the Coyote comes from the factory slightly under-square with a 3.63-inch bore and 3.65-inch stroke. But by opening up the cylinder bore to 3.70-inches you can reduce valve shrouding to increase the cylinder head flow, and even use bigger intake valves for even greater potential. Since most classes allow for up to a 3.700-inch bore with the Cobra Jet's Coyote engine, the folks at SAM Tech planned to take advantage for their latest build.

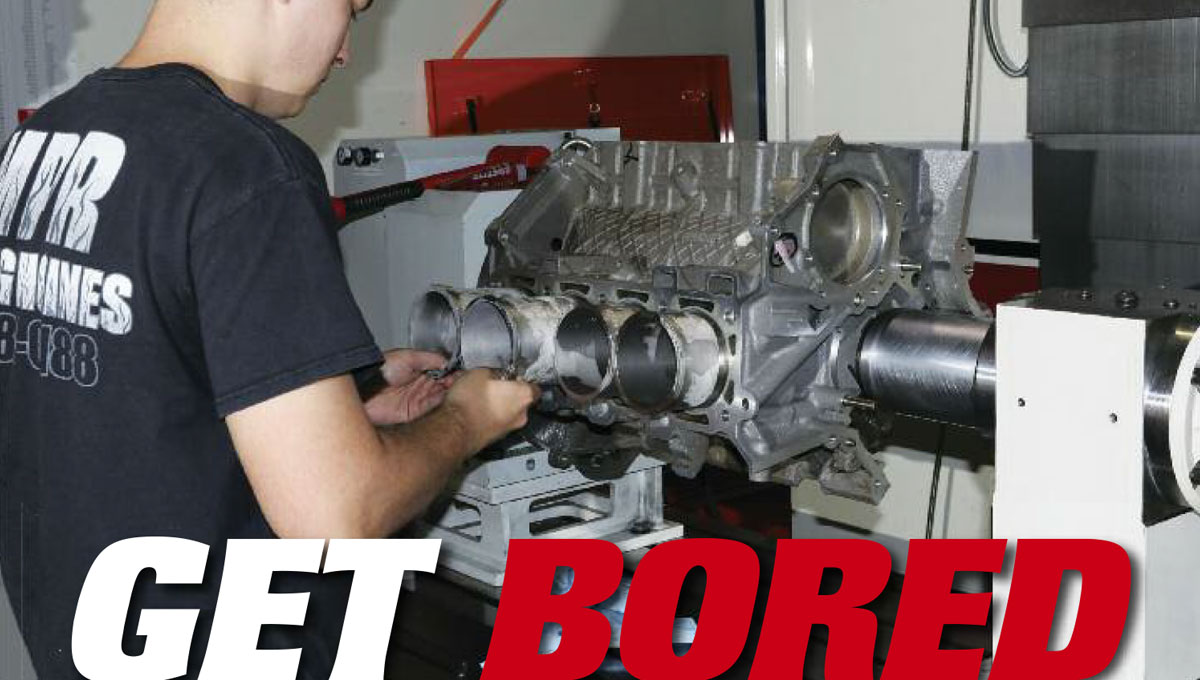

SAM Tech commissioned MPR Racing Engines in Boynton Beach, FL to install a set of Darton sleeves in the Cobra Jet's aluminum FRPP engine block. MPR worked with Darton to develop dry sleeves for the Coyote block, following MPR's successful mod motor program. As is common with OEM aluminum blocks, the Coyote uses cast iron cylinder liners. Unfortunately these liners are only .060-inch-thick. When machined to 3.700-inches, the Darton sleeves are nearly twice as thick and can even be bored to 3.750-inches in naturally aspirated applications. The material is also far superior.

Read about how it all went, >>HERE<<

Posted By: Scott Sparrow

Feb 02,

2017