Written by Ainsley Jacobs

Photography courtesy of the manufacturer

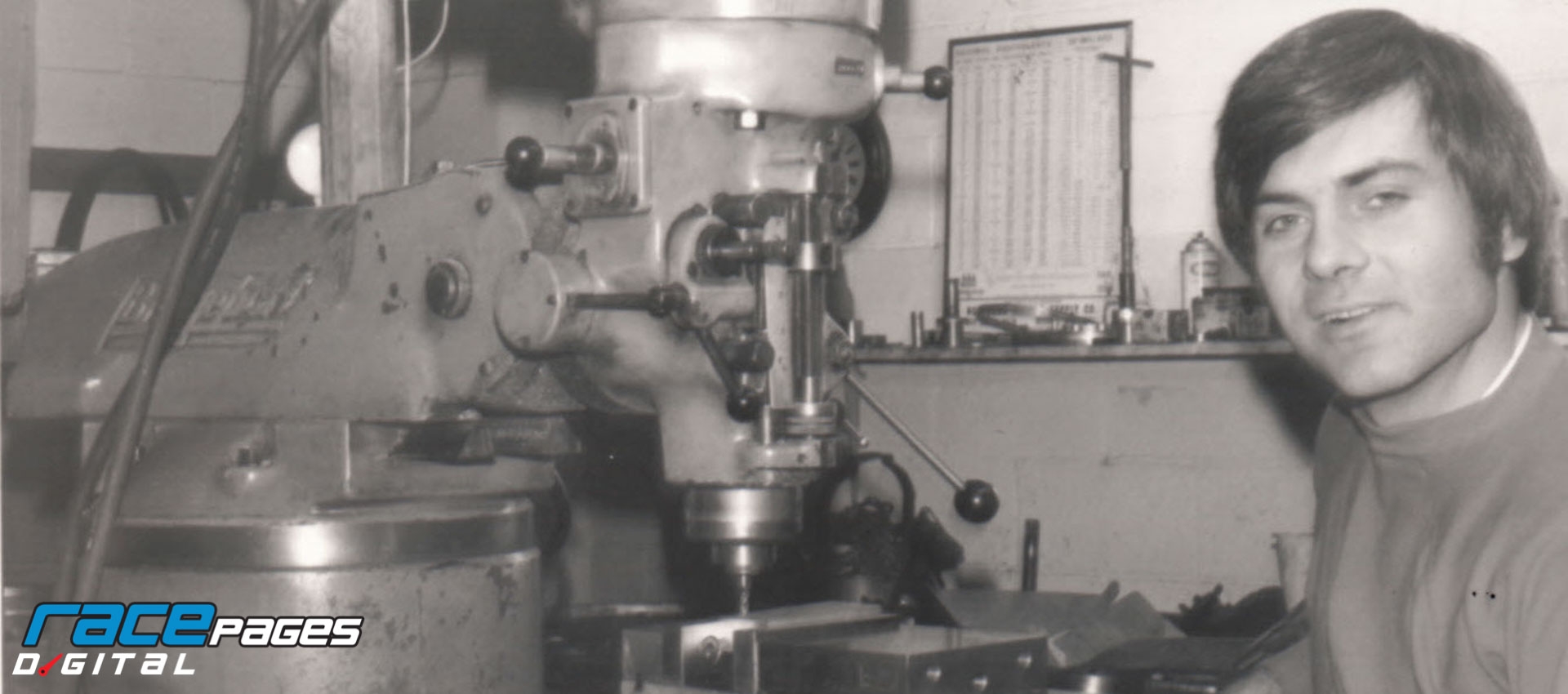

Frustrated by not being able to purchase exactly what he needed elsewhere, Dave Coan founded Coan Engineering in 1976. Now, the company is at the top of the performance torque converter and automatic transmission industry and serves customers of all power levels and budgets across a variety of markets all over the globe.

A longtime drag racer in the NHRA Comp Eliminator category, Dave participated in The Shifters car club local to his hometown of Kokomo, Indiana, for many years. Always inclined to mechanically maintain every aspect of his racecar, Dave wasn’t satisfied with the torque converter and transmission offerings at the time.

“So, he dove in to try and build something better,” explained Dave’s son and partner at Coan Engineering, Jason Coan. “He began making modifications to existing components, and that lead to doing work for other people afterhours from his factory job. He decided to take a leap of faith and quit his day job to go full time.”

Working with a partner in the early stages of building his business, and operating out of The Shifters’ former club headquarters, Dave added on to Coan (pronounced “co-un,” not “cone”) several times in the late 1970s and early 1980s.

Together, the men developed the first lockup torque converter, which was outlawed soon after.

“They went on to develop the first internal transbrake for the Powerglide, Turbo 400, and Turbo 350 transmissions,” shared Jason, proud of his father’s innovations. Coan Engineering also pioneered the use of steel stators in its maximum performance torque converters to withstand the rigors of extreme horsepower.

By 1983, Coan purchased a lot in an industrial park and put up a new 7,200-square-foot facility that Dave never thought he would be able to fill. That eventually grew to 16,000 square feet, and, by 2015, Coan relocated to its third home in Kokomo, which consists of 45,000 square feet and houses more than 40 employees.

In 1999, however, Jason graduated from college with a degree in mechanical engineering and joined his father’s business after having spent many summers working there. His leadership spurred the creation of Coan’s parts and component distribution supply network to independent shops and helped grow the company even further.

Over the years, Coan became nearly self-sufficient in its manufacturing with the exception of a few very niche items.

“We pool together many different skill sets, including CAD/CAM design and engineering, machine programmers, specialized manufacturing staff, and more,” Jason noted of the company’s diversified talent that enables products to be created from development to delivery.

With loads of in-house equipment including multi-axis lathes, five-axis mills, gear cutting machines, a welding and fabrication department, mechanical assembly specialists, customer service staff, sales and tech support team, complete parts department, and more, Coan’s commitment to customer care is coupled with its state-of-the-art torque converter and automatic transmissions product line.

Although the company makes products and components that are found in some of the winningest Pro Modified cars on the planet, as well as at the top levels of off-road truck racing and many marine applications, Coan Engineering got its start from serving grassroots drag racers and that heritage holds strong. As a longtime sponsor of the NMCA Coan Stock/Super Stock category, Coan enjoys giving back to its community by supporting the drag racing industry as a whole. Both Dave and Jason continue to race as well, and especially enjoy the personal, welcoming environment of the NMRA and NMCA.

Photography courtesy of the manufacturer

Frustrated by not being able to purchase exactly what he needed elsewhere, Dave Coan founded Coan Engineering in 1976. Now, the company is at the top of the performance torque converter and automatic transmission industry and serves customers of all power levels and budgets across a variety of markets all over the globe.

A longtime drag racer in the NHRA Comp Eliminator category, Dave participated in The Shifters car club local to his hometown of Kokomo, Indiana, for many years. Always inclined to mechanically maintain every aspect of his racecar, Dave wasn’t satisfied with the torque converter and transmission offerings at the time.

“So, he dove in to try and build something better,” explained Dave’s son and partner at Coan Engineering, Jason Coan. “He began making modifications to existing components, and that lead to doing work for other people afterhours from his factory job. He decided to take a leap of faith and quit his day job to go full time.”

Working with a partner in the early stages of building his business, and operating out of The Shifters’ former club headquarters, Dave added on to Coan (pronounced “co-un,” not “cone”) several times in the late 1970s and early 1980s.

Together, the men developed the first lockup torque converter, which was outlawed soon after.

“They went on to develop the first internal transbrake for the Powerglide, Turbo 400, and Turbo 350 transmissions,” shared Jason, proud of his father’s innovations. Coan Engineering also pioneered the use of steel stators in its maximum performance torque converters to withstand the rigors of extreme horsepower.

By 1983, Coan purchased a lot in an industrial park and put up a new 7,200-square-foot facility that Dave never thought he would be able to fill. That eventually grew to 16,000 square feet, and, by 2015, Coan relocated to its third home in Kokomo, which consists of 45,000 square feet and houses more than 40 employees.

In 1999, however, Jason graduated from college with a degree in mechanical engineering and joined his father’s business after having spent many summers working there. His leadership spurred the creation of Coan’s parts and component distribution supply network to independent shops and helped grow the company even further.

Over the years, Coan became nearly self-sufficient in its manufacturing with the exception of a few very niche items.

“We pool together many different skill sets, including CAD/CAM design and engineering, machine programmers, specialized manufacturing staff, and more,” Jason noted of the company’s diversified talent that enables products to be created from development to delivery.

With loads of in-house equipment including multi-axis lathes, five-axis mills, gear cutting machines, a welding and fabrication department, mechanical assembly specialists, customer service staff, sales and tech support team, complete parts department, and more, Coan’s commitment to customer care is coupled with its state-of-the-art torque converter and automatic transmissions product line.

Although the company makes products and components that are found in some of the winningest Pro Modified cars on the planet, as well as at the top levels of off-road truck racing and many marine applications, Coan Engineering got its start from serving grassroots drag racers and that heritage holds strong. As a longtime sponsor of the NMCA Coan Stock/Super Stock category, Coan enjoys giving back to its community by supporting the drag racing industry as a whole. Both Dave and Jason continue to race as well, and especially enjoy the personal, welcoming environment of the NMRA and NMCA.