Gulf Coast Driveshaft—Super shafts for Bolt-in and Custom Applications

By Evan J. Smith

The driveshaft is a critical component, and in drag racing, there’s hardly a part that’s punished more severely. Connecting the transmission and pinion gear in the rear, the driveshaft endures force and torque delivered by the engine as it transfers that energy, which turns the ring gear to move the vehicle.

To be honest, the driveshaft is one component every racer should consider upgrading, even on a stock vehicle. This holds especially true in today’s modern cars that approach or exceed 4,000 lbs. In addition to improving durability, an aftermarket driveshaft can often made lighter than stock, thus improving performance and safety.

Gulf Coast Driveshafts in Tampa, Florida specializes in high-performance driveshafts and the company offers a range of options for all levels of racing, street performance and off-road use. You can select between steel, aluminum and/or carbon fiber and it offers bolt-in and custom-built shafts for virtually all applications.

“We keep all types and sizes of tubing on the rack,” said Shane Underwood, who co-owns Gulf Coast Driveshaft with his wife Melissa. “We also stock carrier bearings, U-joints, and we have experienced employees capable of building, balancing and delivering just about any shaft configuration. We utilize a clean room for assembly of the carbon shafts and we build shafts for everything from foreign and domestic street cars up to Pro Mods,” he added. Underwood stated that custom aluminum shafts require only a few days with carbon taking just a tad longer due to the cure time and torque testing.

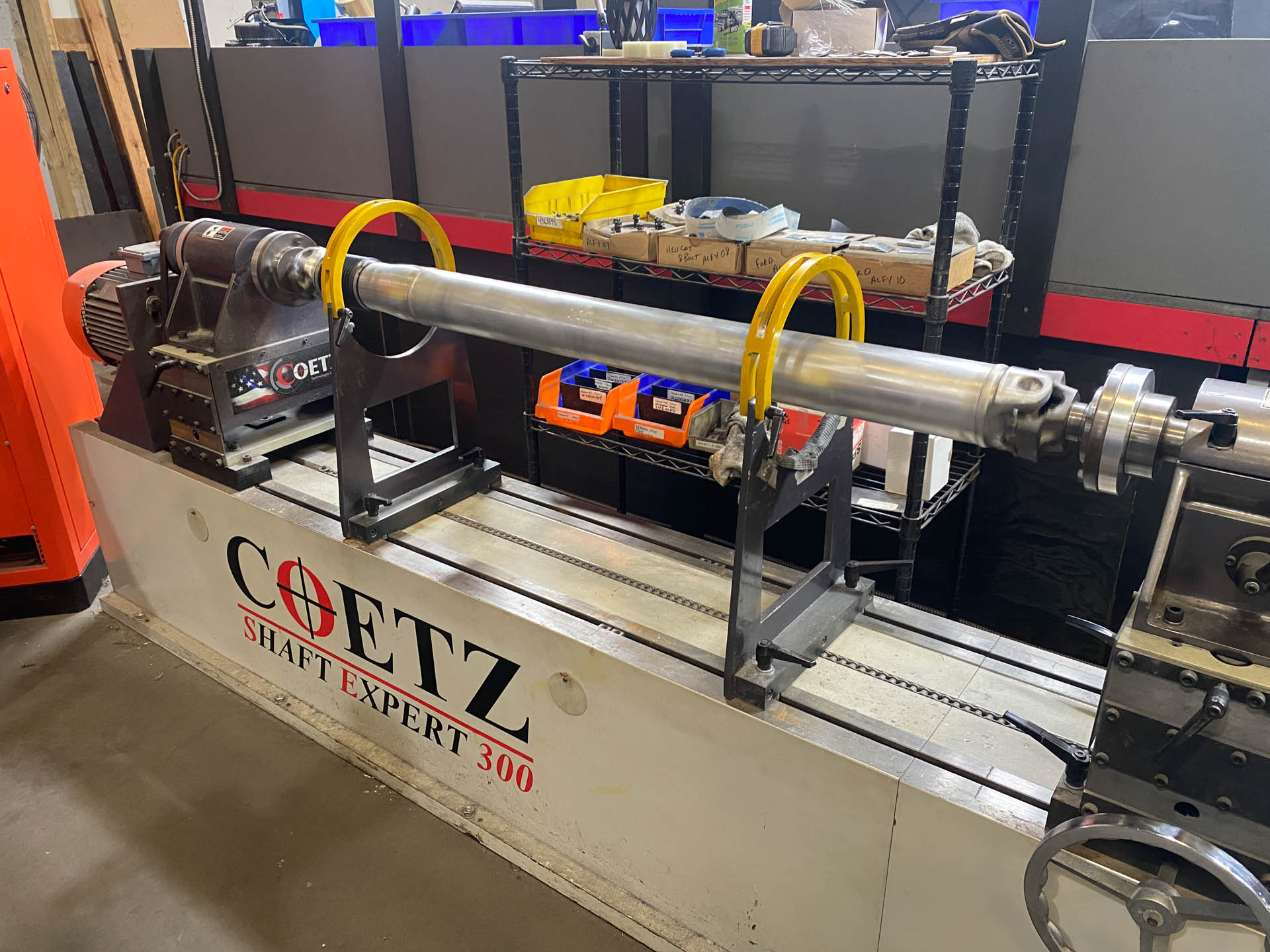

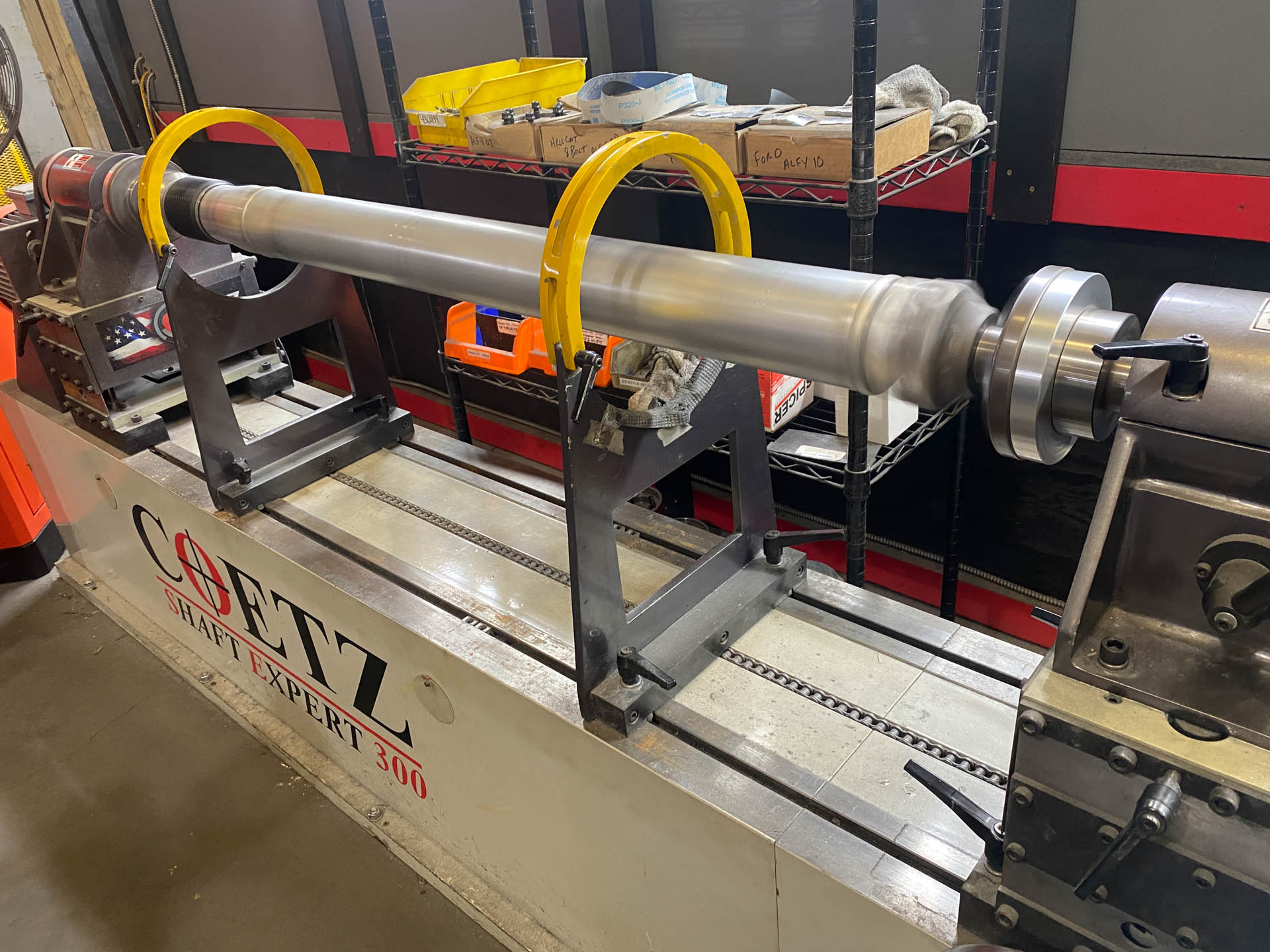

In addition to building high-quality shafts, GCD performs high-speed balancing on its Coetz Shaft Expert 300 spin balancer to ensure smooth, vibration-free operation. This machine allows balancing from 500-5,000 rpm and utilizes a computer-based measuring unit with ramp-up and ramp-down reporting.

Another impressive operation is the in-house torque testing. “We torque test our carbon fiber shafts on a custom-built machine to ensure the bonds are good before any shaft leaves the building,” said Underwood. “I created the machine myself and when we get done torque testing we high-speed balance, then the weights get glued on and generally it’s shipped out that afternoon. Most everyone is on a time crunch so the last thing anyone wants to do is wait for a driveshaft.”

In addition to newly built shafts, Gulf Coast specializes in driveshaft repair. “We realize when you need a repair, you need it done yesterday,” said Underwood. “We know your vehicle has many purposes and uses, whether it’s personal, commercial a daily driver or a race vehicle. We know how frustrating it is when it’s not working as it should, so we do everything to get you back on the road with as little down time as possible. When you bring your driveshaft to Gulf Coast Driveshaft, we make sure your repairs are done with quality parts, by specialized technicians, at a fair price, getting you back on the road to your child’s soccer game or to your next delivery,” he added.

Product Example 2011 – 2014 Mustang GT: Automatic or Manual: Ford Mustang GT 3.25-inch 1350 Series Carbon Fiber Slip Shaft with solid cross non-greaseable U-Joints and hardware.

“We build each 1350 series driveshaft with 3.25-inch carbon fiber tubing, 2024 aluminum bondable yoke shaft and spline sleeve assembly, bond yoke, adapter flange yokes, and performance 1350 series solid cross non greaseable U-joints. Upgraded hardware for the rear flange is included.

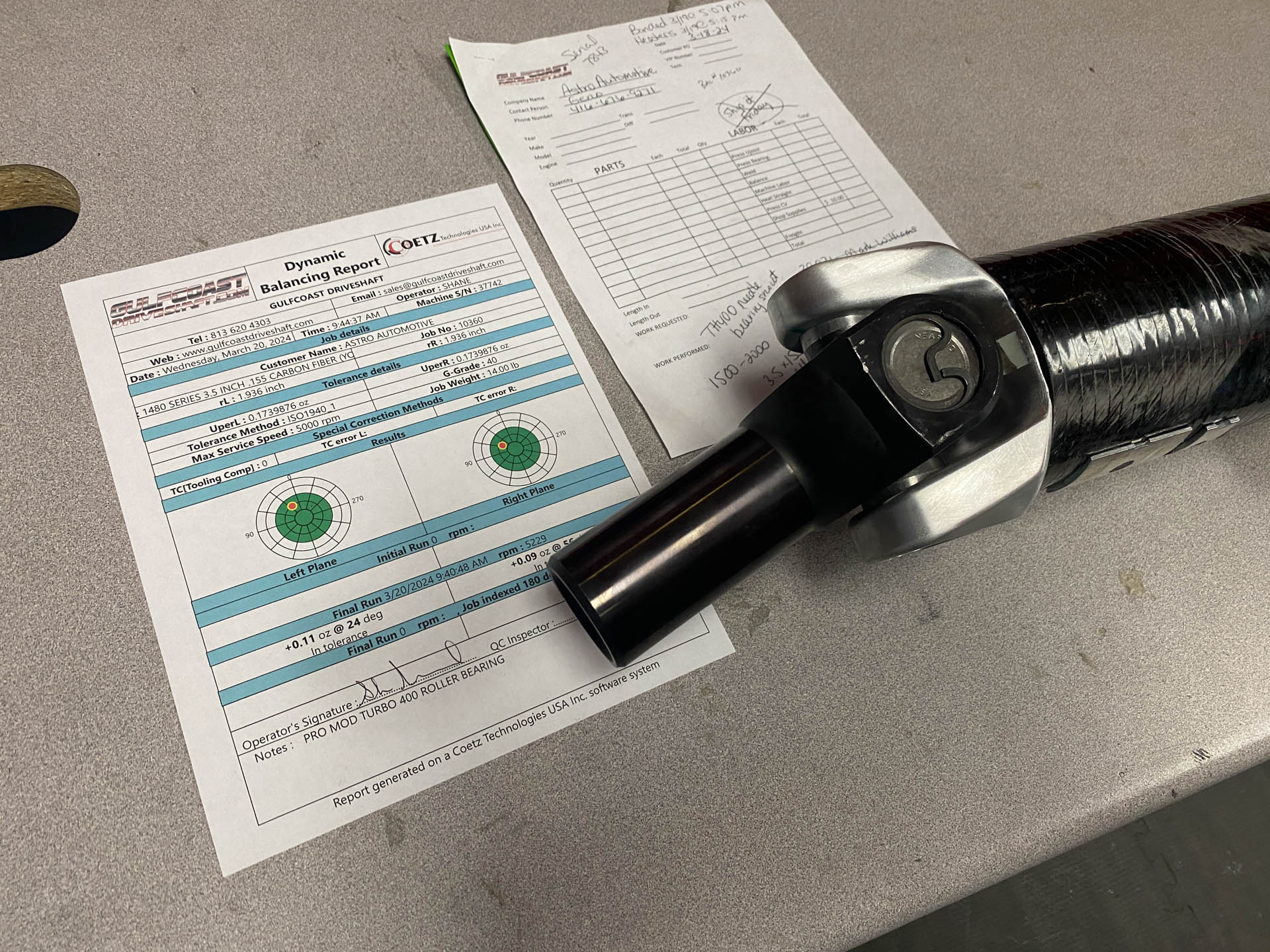

“Factory hardware is reused on the transmission flange and all driveshafts are high speed balanced for performance application on our new Coetz Balancer. A driveshaft balance printout sheet will be provided with each order, giving you peace of mind knowing your driveshaft is balanced within industry standard tolerance. We also torque test each carbon fiber driveshaft before shipping. This ensures the bond is solid and your driveshaft will hold up under high torque application. Please send us a note on how many ft/lbs. of torque your car is capable of so we can test properly. We are one of only three shops in America offering in house torque testing on every carbon fiber shaft.”

Note: Gulf Coast Driveshafts 1350 series driveshaft DOES NOT require additional adapters. “We build each driveshaft with aluminum adapter flanges from Composite Driveline and/or SONNAX. Our driveshaft will bolt directly into your existing OEM flanges on your transmission and differential. This eliminates the need for any additional parts and hardware.”

Components:

“We use 3.25-inch OD carbon fiber tubing from Composite Drivelines and/or NEAPCO,” said Underwood. “There are 14 layers of different directional weaves, creating a stronger, more durable tube. We use a 2024 aluminum bondable yoke shaft and spline sleeve assembly from Composite Drivelines for additional strength vs traditional 6061 aluminum and we use direct bolt-in adapter flanges from Composite Drivelines and SONNAX instead of high speed CVs that require additional adapters and hardware.

“We use only NEAPCO Performance 1350-series solid cross non-greaseable U-Joints in all of our performance and racing shafts. Please keep heat in excess of 250 degrees away from bonded areas for extended periods of time. While it is uncommon to see these temperatures under a moving vehicle, we highly recommend heat shielding/insulation, exhaust/header wrap, to create a barrier of protection. Shafts that fail due to improper heat shielding and subsequent thermal degradation of bonding agent are not covered by warranty. And when installing, please check for any clearance issues. Check the driveshaft tunnel for any bolts, heat shield rub, exhaust clearance, shifter clearance, etc. Make sure nothing rubs the driveshaft. This is your responsibility. Any interference with the driveshaft is not covered under warranty.”

Weight 25 lbs

Dimensions 63 × 6 × 6 in

Model: Fits Mustang 2011, 2012, 2013, 2014

For more information head to: https://gulfcoastdriveshaft.com

By Evan J. Smith

The driveshaft is a critical component, and in drag racing, there’s hardly a part that’s punished more severely. Connecting the transmission and pinion gear in the rear, the driveshaft endures force and torque delivered by the engine as it transfers that energy, which turns the ring gear to move the vehicle.

To be honest, the driveshaft is one component every racer should consider upgrading, even on a stock vehicle. This holds especially true in today’s modern cars that approach or exceed 4,000 lbs. In addition to improving durability, an aftermarket driveshaft can often made lighter than stock, thus improving performance and safety.

Gulf Coast Driveshafts in Tampa, Florida specializes in high-performance driveshafts and the company offers a range of options for all levels of racing, street performance and off-road use. You can select between steel, aluminum and/or carbon fiber and it offers bolt-in and custom-built shafts for virtually all applications.

“We keep all types and sizes of tubing on the rack,” said Shane Underwood, who co-owns Gulf Coast Driveshaft with his wife Melissa. “We also stock carrier bearings, U-joints, and we have experienced employees capable of building, balancing and delivering just about any shaft configuration. We utilize a clean room for assembly of the carbon shafts and we build shafts for everything from foreign and domestic street cars up to Pro Mods,” he added. Underwood stated that custom aluminum shafts require only a few days with carbon taking just a tad longer due to the cure time and torque testing.

In addition to building high-quality shafts, GCD performs high-speed balancing on its Coetz Shaft Expert 300 spin balancer to ensure smooth, vibration-free operation. This machine allows balancing from 500-5,000 rpm and utilizes a computer-based measuring unit with ramp-up and ramp-down reporting.

Another impressive operation is the in-house torque testing. “We torque test our carbon fiber shafts on a custom-built machine to ensure the bonds are good before any shaft leaves the building,” said Underwood. “I created the machine myself and when we get done torque testing we high-speed balance, then the weights get glued on and generally it’s shipped out that afternoon. Most everyone is on a time crunch so the last thing anyone wants to do is wait for a driveshaft.”

In addition to newly built shafts, Gulf Coast specializes in driveshaft repair. “We realize when you need a repair, you need it done yesterday,” said Underwood. “We know your vehicle has many purposes and uses, whether it’s personal, commercial a daily driver or a race vehicle. We know how frustrating it is when it’s not working as it should, so we do everything to get you back on the road with as little down time as possible. When you bring your driveshaft to Gulf Coast Driveshaft, we make sure your repairs are done with quality parts, by specialized technicians, at a fair price, getting you back on the road to your child’s soccer game or to your next delivery,” he added.

Product Example 2011 – 2014 Mustang GT: Automatic or Manual: Ford Mustang GT 3.25-inch 1350 Series Carbon Fiber Slip Shaft with solid cross non-greaseable U-Joints and hardware.

“We build each 1350 series driveshaft with 3.25-inch carbon fiber tubing, 2024 aluminum bondable yoke shaft and spline sleeve assembly, bond yoke, adapter flange yokes, and performance 1350 series solid cross non greaseable U-joints. Upgraded hardware for the rear flange is included.

“Factory hardware is reused on the transmission flange and all driveshafts are high speed balanced for performance application on our new Coetz Balancer. A driveshaft balance printout sheet will be provided with each order, giving you peace of mind knowing your driveshaft is balanced within industry standard tolerance. We also torque test each carbon fiber driveshaft before shipping. This ensures the bond is solid and your driveshaft will hold up under high torque application. Please send us a note on how many ft/lbs. of torque your car is capable of so we can test properly. We are one of only three shops in America offering in house torque testing on every carbon fiber shaft.”

Note: Gulf Coast Driveshafts 1350 series driveshaft DOES NOT require additional adapters. “We build each driveshaft with aluminum adapter flanges from Composite Driveline and/or SONNAX. Our driveshaft will bolt directly into your existing OEM flanges on your transmission and differential. This eliminates the need for any additional parts and hardware.”

Components:

“We use 3.25-inch OD carbon fiber tubing from Composite Drivelines and/or NEAPCO,” said Underwood. “There are 14 layers of different directional weaves, creating a stronger, more durable tube. We use a 2024 aluminum bondable yoke shaft and spline sleeve assembly from Composite Drivelines for additional strength vs traditional 6061 aluminum and we use direct bolt-in adapter flanges from Composite Drivelines and SONNAX instead of high speed CVs that require additional adapters and hardware.

“We use only NEAPCO Performance 1350-series solid cross non-greaseable U-Joints in all of our performance and racing shafts. Please keep heat in excess of 250 degrees away from bonded areas for extended periods of time. While it is uncommon to see these temperatures under a moving vehicle, we highly recommend heat shielding/insulation, exhaust/header wrap, to create a barrier of protection. Shafts that fail due to improper heat shielding and subsequent thermal degradation of bonding agent are not covered by warranty. And when installing, please check for any clearance issues. Check the driveshaft tunnel for any bolts, heat shield rub, exhaust clearance, shifter clearance, etc. Make sure nothing rubs the driveshaft. This is your responsibility. Any interference with the driveshaft is not covered under warranty.”

Weight 25 lbs

Dimensions 63 × 6 × 6 in

Model: Fits Mustang 2011, 2012, 2013, 2014

For more information head to: https://gulfcoastdriveshaft.com