Where It All Started—Circle D Specialties

Written by Ainsley Jacobs

Photography courtesy of the manufacturer

Since its founding in the 1970s, Circle D Specialties expanded greatly over the years. Although the company evolved along the way, its foundation of continuously improving and raising the bar with its torque converters and other products remains rock solid.

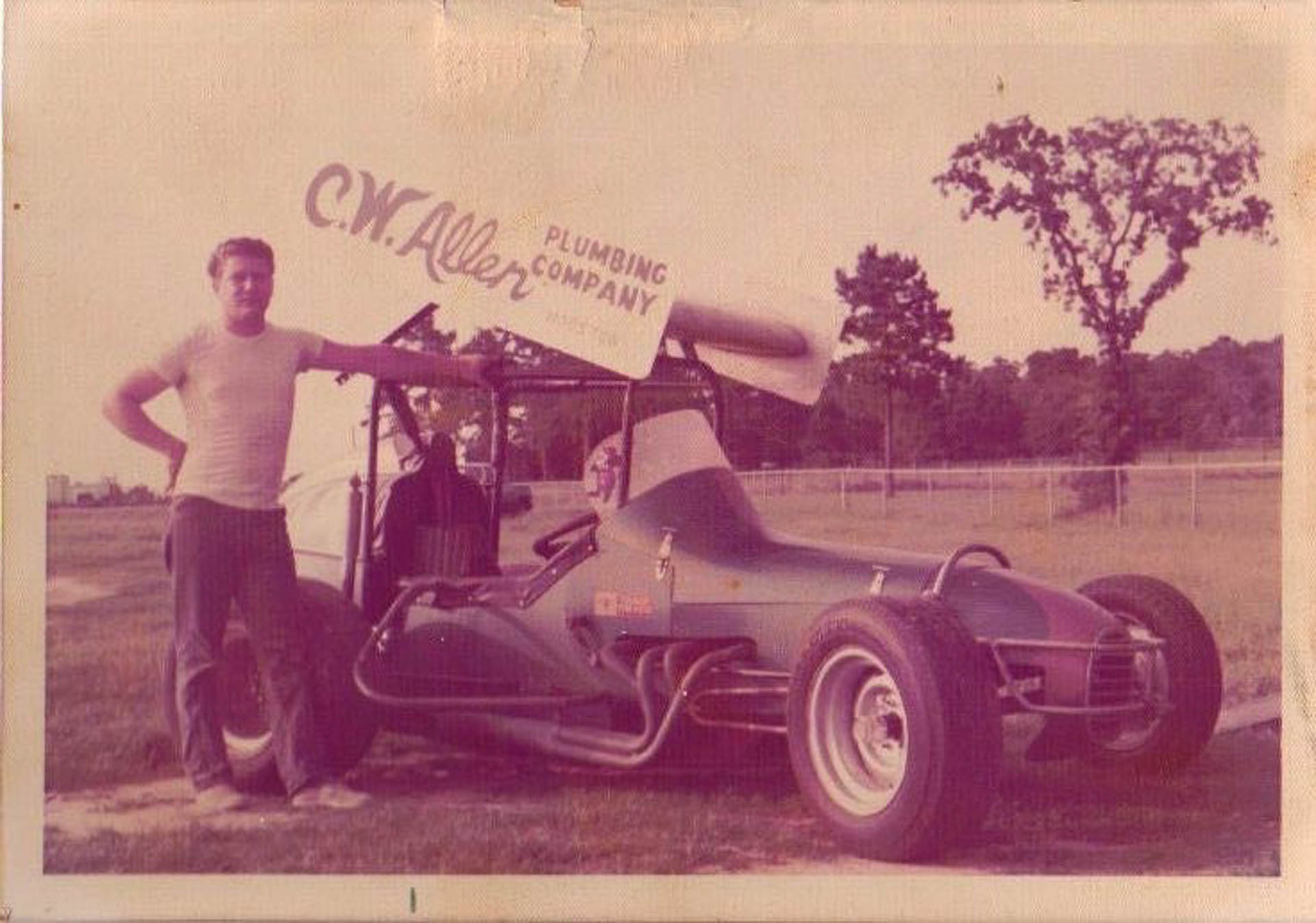

In the early 1970s, Dennis Sehorn was interested in opening a paint and body facility. A jack of all trades with solid wrenching skills, the mechanically minded man was an active dirt track and sprint car racer. “He stopped in to use the phone at a friend’s shop to call about a place he was interested in leasing,” noted Chris Sehorn, Dennis’ son and present owner of Circle D Specialties. “His friend overheard the conversation and offered him a job in his transmission shop instead.”

Dennis worked his way up over the years, to the point where he was practically running his friend’s business. Instead, he decided to go into business for himself. Together with his wife, Patricia, just a few months after Chris was born, the couple founded Circle D Transmission in 1976 in a small, two-bay shop in Houston, Texas. Although many people think the name refers to overdrive automatic transmissions, it was a reference to the founder’s “circle” track days and his “D” initial.

“At first, they did general automotive repair and later focused on transmissions,” shared Chris, whose parents’ business started focusing more on transmissions towards the late 1970s. A progressively minded and forward-thinking entrepreneur, Dennis sought out ways to expand his business. “Eventually, he decided to start building his own OE-style, standard replacement torque converters for other shops in the greater Houston area. As a result, Circle D Specialties was formed in the late ‘80s.”

When Chris was about 19 years old, he realized he would rather work in the family business than stay in the corporate world. He called his father and joined the Circle D team in the mid-1990s, working his way up over the years from shop cleaning and parts organization to building transmissions and converters.

By the early 2000s, Chris’s responsibilities grew significantly and he found himself handling many of the day-to-day operations. “I wanted to get more into the performance side of things. There wasn’t a ton of information on the Internet back then, but we had a lot of great customers working with us and providing data and feedback for us to build better products,” said Chris who, along with his wife Ann, purchased Circle D Specialties from his parents in 2004.

Circle D purchased its first CNC machines in 2006 and began cutting front covers and billet components in-house; the OE side of things began winding down around 2008 and, by 2010, the company was strictly performance-focused. “Circle D Specialties became known for its record-setting converters,” he continued proudly. “We were first-to-market for many transmissions and dominated in the Mustang and Coyote crowds.”

In 2014, Chris’s company outgrew his father’s old, 2,500-square-foot location and moved into a new 21,000-square-foot building, still in Houston. By 2021, though, Circle D needed more space yet again and relocated once more to a purpose-built 58,000-square-foot facility with more than 40 employees under the roof.

Now, with 13 CNC machines and plenty of other high-end manufacturing equipment, Circle D manufactures as much as possible in-house. As a result, the company can respond quickly to market demand by introducing new products, upgraded designs, and improved features all without enduring the delay of mass production typical of other manufacturers.

“We do a complete research and development process, with computational fluid dynamics utilized to design our custom-made stators,” Chris elaborated. “We don’t use a traditional flat-blade in our converters, and the software lets us simulate how our converters work out of the hole, how they couple down the track, their efficiency on the top end, and more.”

“Our research and development process utilizes computational fluid dynamics (CFD) to guide the design of our custom-made stators,” Chris elaborated. Circle D uses software to simulate the torque converter function and generate data points that establish a K factor curve for each unique design. “This K factor curve informs us as to what may be expected from the converter with respect to flash characteristics, coupling throughout the run, efficiency at the end of the run, and how hard the converter will hit at the starting line.”

While Circle D does offer some traditional, flat-blade stators, the company’s focus is primarily on its unique airfoil stators which include exponential-blade design options. Additionally, Circle D’s two five-axis CNC machining centers allow for the production of virtually any style of stator needed.

For the NMRA family of racers, Circle D Specialties proudly sponsors the True Street category. “We’re car guys, too, and we get it. We have a big respect for the passion and drive of our racers, so we’re committed to always helping them run quicker and faster by looking at the data and seeing where we can improve,” affirmed Chris.

Since its inception, Circle D Specialties transformed from a small OE-style supply shop to a performance powerhouse that produces exceptional torque converters while providing unparalleled knowledge and outstanding customer service. In November of 2023, Circle D acquired performance transmission case manufacturer, Reid Racing. By providing torque converter solutions for everything from two-speed Powerglide transmissions to three-speed Turbo 400s and even modern six-, eight-, and 10-speed automatics, Circle D raised the bar on what’s possible.

Written by Ainsley Jacobs

Photography courtesy of the manufacturer

Since its founding in the 1970s, Circle D Specialties expanded greatly over the years. Although the company evolved along the way, its foundation of continuously improving and raising the bar with its torque converters and other products remains rock solid.

In the early 1970s, Dennis Sehorn was interested in opening a paint and body facility. A jack of all trades with solid wrenching skills, the mechanically minded man was an active dirt track and sprint car racer. “He stopped in to use the phone at a friend’s shop to call about a place he was interested in leasing,” noted Chris Sehorn, Dennis’ son and present owner of Circle D Specialties. “His friend overheard the conversation and offered him a job in his transmission shop instead.”

Dennis worked his way up over the years, to the point where he was practically running his friend’s business. Instead, he decided to go into business for himself. Together with his wife, Patricia, just a few months after Chris was born, the couple founded Circle D Transmission in 1976 in a small, two-bay shop in Houston, Texas. Although many people think the name refers to overdrive automatic transmissions, it was a reference to the founder’s “circle” track days and his “D” initial.

“At first, they did general automotive repair and later focused on transmissions,” shared Chris, whose parents’ business started focusing more on transmissions towards the late 1970s. A progressively minded and forward-thinking entrepreneur, Dennis sought out ways to expand his business. “Eventually, he decided to start building his own OE-style, standard replacement torque converters for other shops in the greater Houston area. As a result, Circle D Specialties was formed in the late ‘80s.”

When Chris was about 19 years old, he realized he would rather work in the family business than stay in the corporate world. He called his father and joined the Circle D team in the mid-1990s, working his way up over the years from shop cleaning and parts organization to building transmissions and converters.

By the early 2000s, Chris’s responsibilities grew significantly and he found himself handling many of the day-to-day operations. “I wanted to get more into the performance side of things. There wasn’t a ton of information on the Internet back then, but we had a lot of great customers working with us and providing data and feedback for us to build better products,” said Chris who, along with his wife Ann, purchased Circle D Specialties from his parents in 2004.

Circle D purchased its first CNC machines in 2006 and began cutting front covers and billet components in-house; the OE side of things began winding down around 2008 and, by 2010, the company was strictly performance-focused. “Circle D Specialties became known for its record-setting converters,” he continued proudly. “We were first-to-market for many transmissions and dominated in the Mustang and Coyote crowds.”

In 2014, Chris’s company outgrew his father’s old, 2,500-square-foot location and moved into a new 21,000-square-foot building, still in Houston. By 2021, though, Circle D needed more space yet again and relocated once more to a purpose-built 58,000-square-foot facility with more than 40 employees under the roof.

Now, with 13 CNC machines and plenty of other high-end manufacturing equipment, Circle D manufactures as much as possible in-house. As a result, the company can respond quickly to market demand by introducing new products, upgraded designs, and improved features all without enduring the delay of mass production typical of other manufacturers.

“We do a complete research and development process, with computational fluid dynamics utilized to design our custom-made stators,” Chris elaborated. “We don’t use a traditional flat-blade in our converters, and the software lets us simulate how our converters work out of the hole, how they couple down the track, their efficiency on the top end, and more.”

“Our research and development process utilizes computational fluid dynamics (CFD) to guide the design of our custom-made stators,” Chris elaborated. Circle D uses software to simulate the torque converter function and generate data points that establish a K factor curve for each unique design. “This K factor curve informs us as to what may be expected from the converter with respect to flash characteristics, coupling throughout the run, efficiency at the end of the run, and how hard the converter will hit at the starting line.”

While Circle D does offer some traditional, flat-blade stators, the company’s focus is primarily on its unique airfoil stators which include exponential-blade design options. Additionally, Circle D’s two five-axis CNC machining centers allow for the production of virtually any style of stator needed.

For the NMRA family of racers, Circle D Specialties proudly sponsors the True Street category. “We’re car guys, too, and we get it. We have a big respect for the passion and drive of our racers, so we’re committed to always helping them run quicker and faster by looking at the data and seeing where we can improve,” affirmed Chris.

Since its inception, Circle D Specialties transformed from a small OE-style supply shop to a performance powerhouse that produces exceptional torque converters while providing unparalleled knowledge and outstanding customer service. In November of 2023, Circle D acquired performance transmission case manufacturer, Reid Racing. By providing torque converter solutions for everything from two-speed Powerglide transmissions to three-speed Turbo 400s and even modern six-, eight-, and 10-speed automatics, Circle D raised the bar on what’s possible.